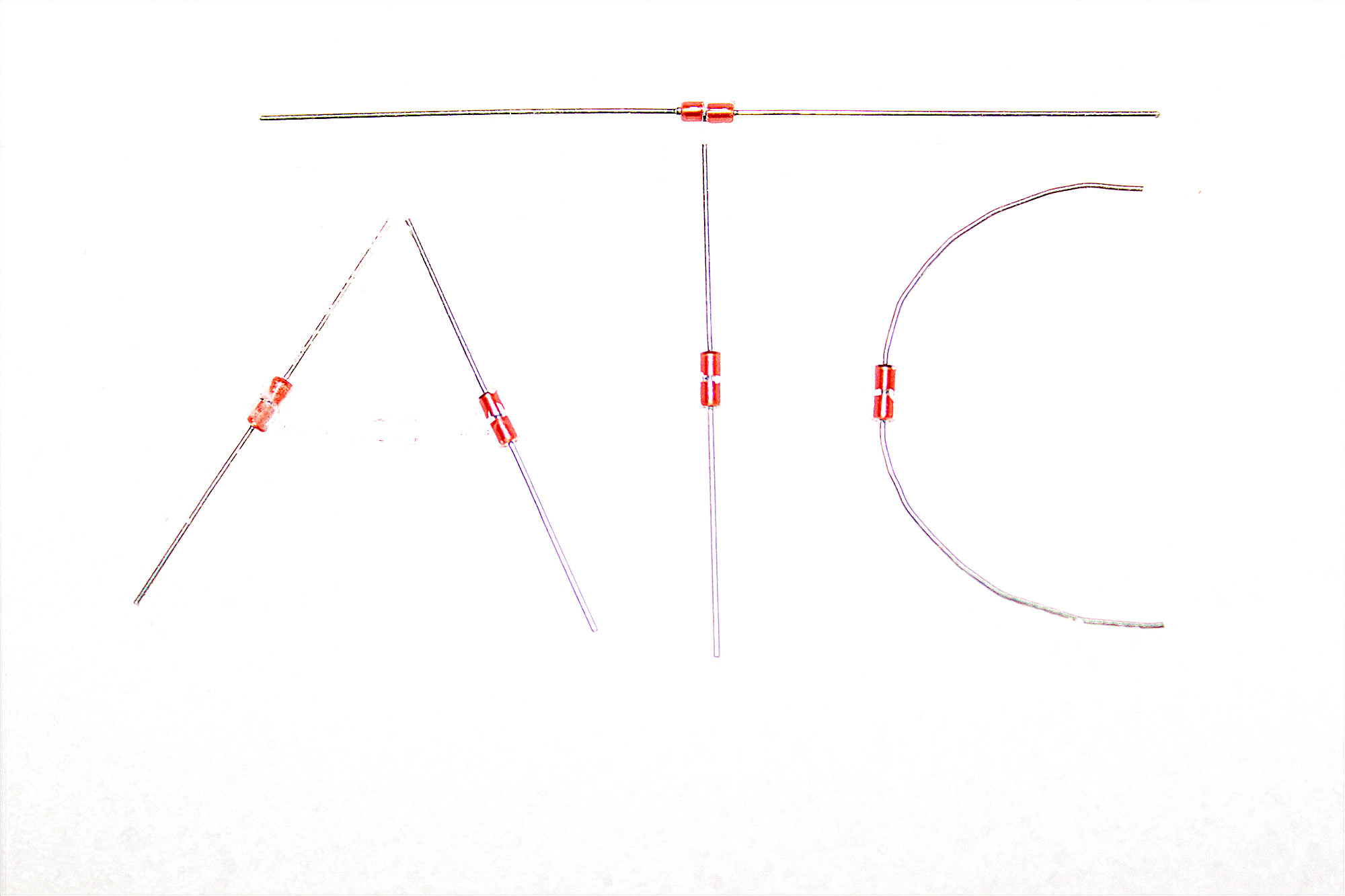

NTC is an acronym for Negative Temperature Coefficient, which means a negative temperature coefficient, refers to a large negative temperature coefficient of semiconductor materials or components, the so-called NTC thermistor is a negative temperature coefficient thermistor. It is based on manganese, cobalt, nickel and copper and other metal oxides as the main material, the use of ceramics from the process. These materials are metal oxide semiconductor nature, because in the way completely similar conductive germanium, silicon and other semiconductor materials.

Low temperature, these oxides carrier materials (electronic and hole) less the number, the higher its resistance value; With the temperature increase in the number of carriers, so reduce the resistance value. NTC thermistor changes at room temperature range of 10O ~ 1000000 ohms, temperature coefficient of -6.5% -2%. NTC thermistor can be widely used in temperature measurement, temperature compensation, and so on surge current suppression.

NTC (Negative Temperature Coeff1Cient) is the increase in resistance with temperature exponentially decreasing relationship, with negative temperature coefficient thermistor of the phenomena and materials. The material is the use of manganese, copper, silicon, cobalt, iron, nickel, zinc, such as two or more full of mixed metal oxides, forming and sintering processes from the semiconductor ceramics, can be made with a negative temperature coefficient (NTC) thermistor. Its resistivity and material constants with the proportion of material composition, sintering atmosphere, sintering temperature and structure of the state vary. It appeared to silicon carbide, selenium and tin, tantalum nitride, etc., represented by the Department of non-oxide materials NTC thermistor.

NTC thermistors are semiconducting ceramics or other structure of spinel structure oxide ceramics with negative temperature coefficient of resistance value can be approximated as follows:

Where RT, RT0 temperature, respectively T, T0, when the resistance value, Bn for the material constants. Ceramic grain temperature changes as a result of their resistance to change, which is determined by the semiconductor properties.

NTC thermistor has experienced a long development stage. In 1834, scientists discovered the first silver sulfide have negative temperature coefficient characteristics. In 1930, scientists found that cuprous oxide – copper oxide also has a negative temperature coefficient of performance, and to make use of the equipment in the air temperature compensation circuit. Subsequently, due to the continuous development of transistor technology, the study of thermal resistor made significant progress.

Developed in 1960 Thermistor N1C. NTC NTC thermistors are widely used in temperature measurement, temperature control, temperature compensation and so on. Here’s an example of temperature measurement applications, NTC thermistor temperature measurement using the principle shown in Figure 4.

It is generally the measurement range -10 ~ +300 ℃, can manage to -200 ~ +10 ℃, can even be used to +300 ~ +1200 ℃ environment used for temperature measurement. RT for the NTC thermistor; R2 and R3 is a balanced resistance bridge; R1 resistance to the start; R4 for the full-scale resistance, header checksum, also known as calibration resistor; R7, R8 and W for the partial pressure resistance, bridge to provide a stable DC power supply. R6 and header (microamp table) in series, starting form the first amendment to limit the scale and form the first current flows through the role. R5 in parallel with the table first, since the protective effect. In the unbalanced bridge arm (that is, R1, RT) access a thermistor for temperature sensing element probe RT.

Since the thermistor’s resistance changes with temperature changes, so then in the bridge table between the first diagonal corresponding changes in the instructions. This is the thermistor thermometer works.

Thermistor thermometer accuracy can reach 0.1 ℃, temperature and time can be as small as the following 10s. It applies not only to the granary thermometer, but also can be applied to food storage, medical and health, scientific farming, marine, deep well, high-altitude, glaciers and other aspects of temperature measurement.