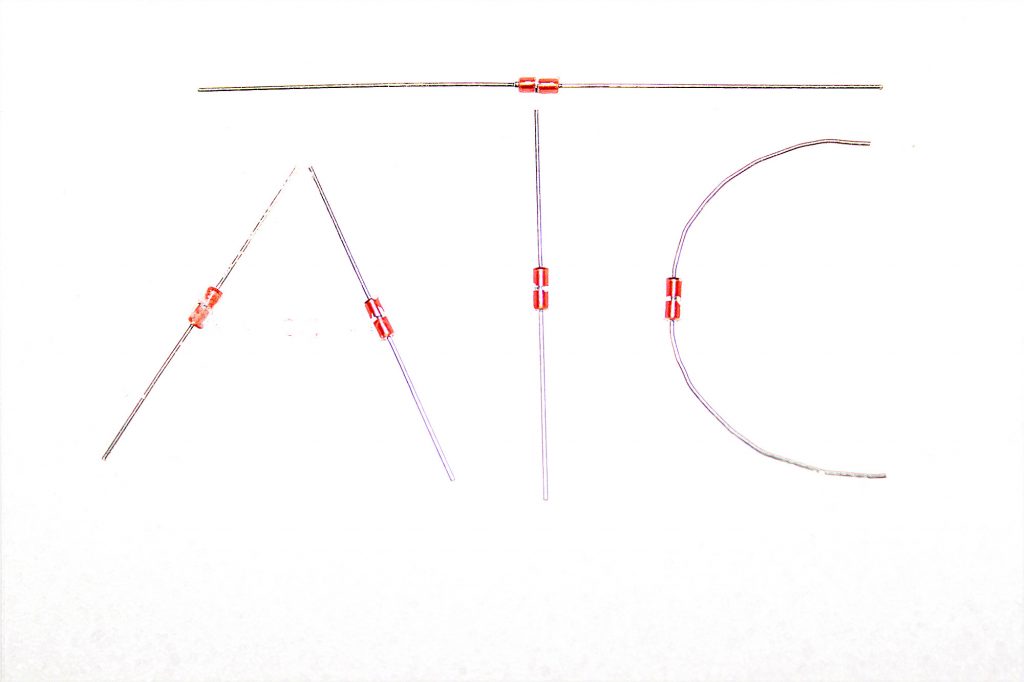

The main component of the thermistor sensor is a thermistor. When there is heat radiation around the heat-sensitive material, it absorbs the radiant heat, causing an increase in temperature, causing a change in the resistance of the material.

1. Thermistor sensor temperature measurement

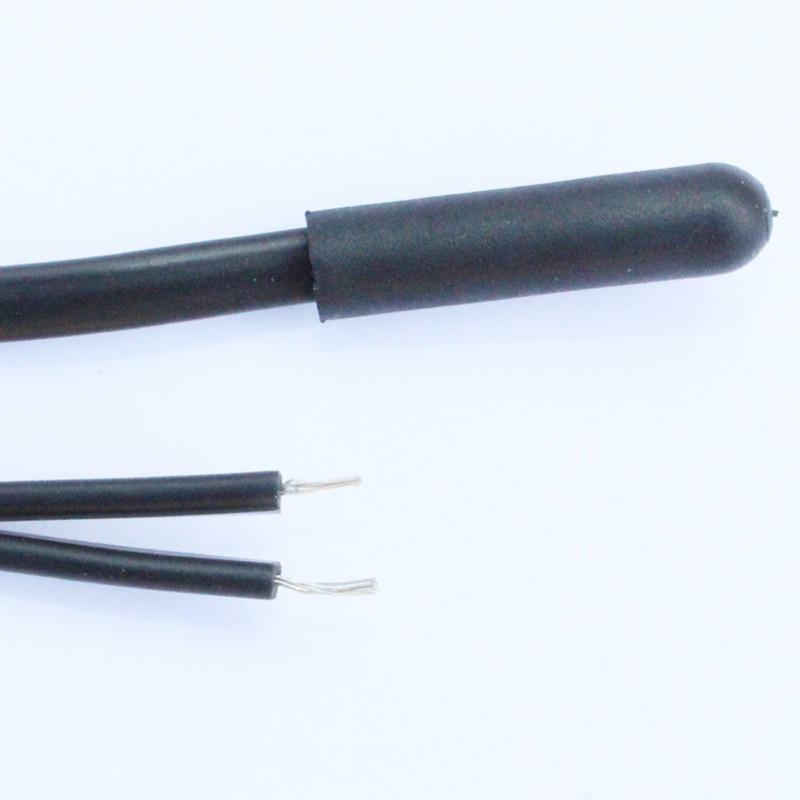

As a thermistor sensor for measuring temperature, the structure is relatively simple and inexpensive. Thermistors without an outer protective layer can only be used in dry places; sealed thermistors are not afraid of moisture and can be used in harsh environments. Since the resistance value of the thermistor sensor is large, the resistance and contact resistance of the connecting wire can be neglected, so the thermistor sensor can be applied in the long-distance measurement temperature of several kilometers, and the measuring circuit adopts a bridge. It can also be used as other temperature measurement and temperature control circuits by using its principle.

2. Thermistor sensor is used for temperature compensation

The thermistor sensor compensates for the humidity of certain components over a range of temperatures. For example, the moving coil in the moving-head type meter head is wound by a copper wire. The temperature rises and the resistance increases, causing a temperature error. Therefore, the negative temperature coefficient thermistor and the manganese copper wire resistance can be connected in parallel in the loop of the moving coil and then connected in series with the compensated component, thereby offsetting the error caused by the temperature change. In transistor circuits and logarithmic amplifiers, thermistors are also commonly used to compensate circuits to compensate for drift errors due to temperature.

3. Thermistor sensor’s overheat protection

Overheat protection is directly protected against indirect protection. For small current applications, the thermistor sensor can be directly connected to the load to prevent overheating damage to protect the device. For large current applications, it can be used to protect relays and transistor circuits. In either case, the thermistor is tightly integrated with the protected device, allowing for sufficient heat exchange between the two. Once overheated, the thermistor protects. For example, a sudden thermistor sensor is embedded in the stator winding of the motor and connected in series with the relay. When the motor is overloaded, the stator current increases, causing heat. When the temperature is greater than the sudden change point, the current in the circuit can be mutated to a few tens of milliamps within a few tenths of milliamperes, so the relay acts to achieve overheat protection.

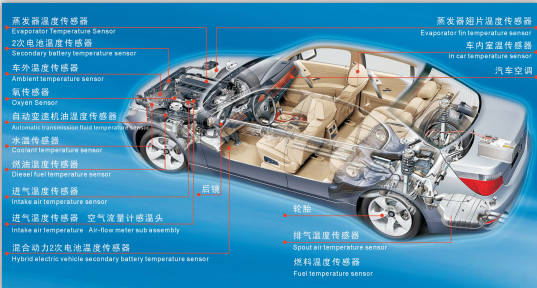

4. Thermistor sensor is used for liquid level measurement

A certain heating current is applied to the NTC thermistor sensor, and its surface temperature will be higher than the surrounding air temperature, at which time its resistance is small. When the liquid is higher than its installation height, the liquid will take away its heat, causing the temperature to drop and the resistance to rise. Judging its resistance change, you can know whether the liquid level is lower than the set value. The oil level alarm sensor in the car fuel tank is made using the above principle. Thermistors are also used in automobiles to measure oil temperature, cooling water mixing, etc.