Now that technology is developing rapidly, this article will give you an in-depth explanation of the characteristics and application range of glass-sealed thermistors. I hope to help everyone.

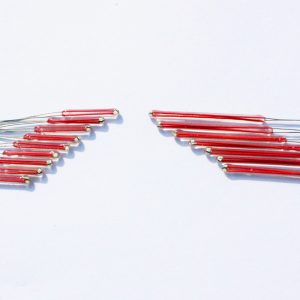

The glass-sea thermistor is a thermistor sealed with insulating glass. Because the glass is insulated, the thermistor is not affected by the extra temperature, which greatly improves the sensitivity and accuracy of the control. The appearance of the glass-sea thermistor is as follows:

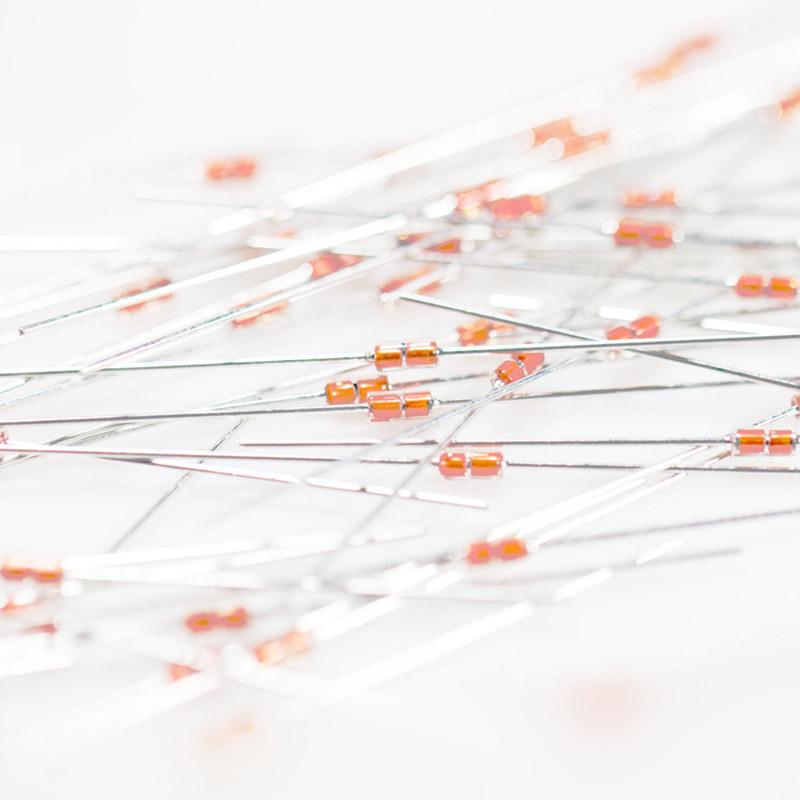

The thermistor is a type of sensitive component and is divided into a positive temperature coefficient thermistor and a negative temperature coefficient thermistor according to the temperature coefficient. Typical characteristics of thermistors are temperature sensitive and exhibit different resistance values at different temperatures. The positive temperature coefficient thermistor has a higher resistance value at higher temperatures, and the lower the resistance value of the negative temperature coefficient thermistor at higher temperatures, they belong to the semiconductor device.

The glass-sealed thermistor mainly plays the role of temperature compensation. The thermistor has several material packaging forms, such as epoxy resin, SMD, and glass. . Etc., the main feature of glass seal in NTC is high temperature resistance and moisture resistance, but compared with other packages, the reaction speed is slower, about ten seconds! The other briefs are as follows:

1. It is made by the combination of ceramic technology and semiconductor technology, and the pure glass package structure is taken out from both ends.

2. Features

• Good stability and high reliability

• The resistance range is 1~200KΩ wide

• High precision of resistance

• Due to the glass package, it can be used in harsh environments such as high temperature and high humidity.

• Small size, light weight and sturdy construction for easy installation (on printed circuit boards)

• Thermal sensing speed, sensitivity

3. Application range

• Temperature control and temperature detection of household appliances (such as air conditioners, microwave ovens, electric fans, electric heaters, etc.)

• Temperature detection or temperature compensation for office automation equipment (such as copiers, printers, etc.)

• Temperature control and inspection of industrial, medical, environmental, meteorological and food processing equipment

• Level indication and flow measurement

•cell phone battery

• Temperature compensation for meter coils, integrated circuits, quartz crystal oscillators and thermocouples