The importance of NTC thermistors to a product is like human hands. Without them, people can live, but they can’t do anything! This hand has to be sensitive!

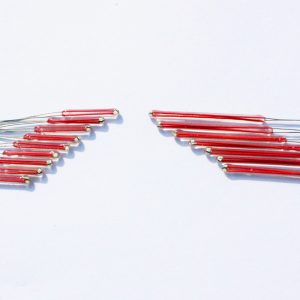

Tips: The most important thing for NTC thermistors is life! After withstanding various high-precision, high-sensitivity, high-reliability, ultra-high temperature, and strong pressure tests, it still works stably for a long time.

Therefore, you must first use: Long-life NTC thermistor! This way you can guarantee long-life electrical products. The reason is simple. No one’s life is gone, no matter how capable it is.

Airmate rice cookers, Estar thermometers, Pinson rechargeable batteries, and other brands are using this standard to select NTC thermistors.

Hybrid / pure electric vehicles are needed in the domestic situation

At present, “energy saving and emission reduction” is one of the main directions for the development of the global industry. On the one hand, it refers to the need to continue to develop “energy saving and emission reduction” technologies for internal combustion engine engines. On the other hand, it refers to the need to strengthen the development of new energy vehicles. Among them, hybrid / pure electric vehicles are the main directions. (Very significant)

Undoubtedly, internal combustion engine vehicles will occupy a relatively large proportion of applications for a long time, which requires further optimization of internal combustion engine technology so that its fuel consumption can be reduced by about 30%. At the same time, another conversion trend worthy of attention is the development of electric vehicles. The biggest challenge now is that the battery still has major problems such as too large, too expensive, too heavy, and insufficient travel. In addition, hybrid / pure High temperatures in batteries and drivers in electric vehicles can also be dangerous at any time. These are important issues that need to be addressed worldwide. (Battery performance requirements and safety issues must be addressed)

Application of NTC temperature sensor in three aspects of automotive

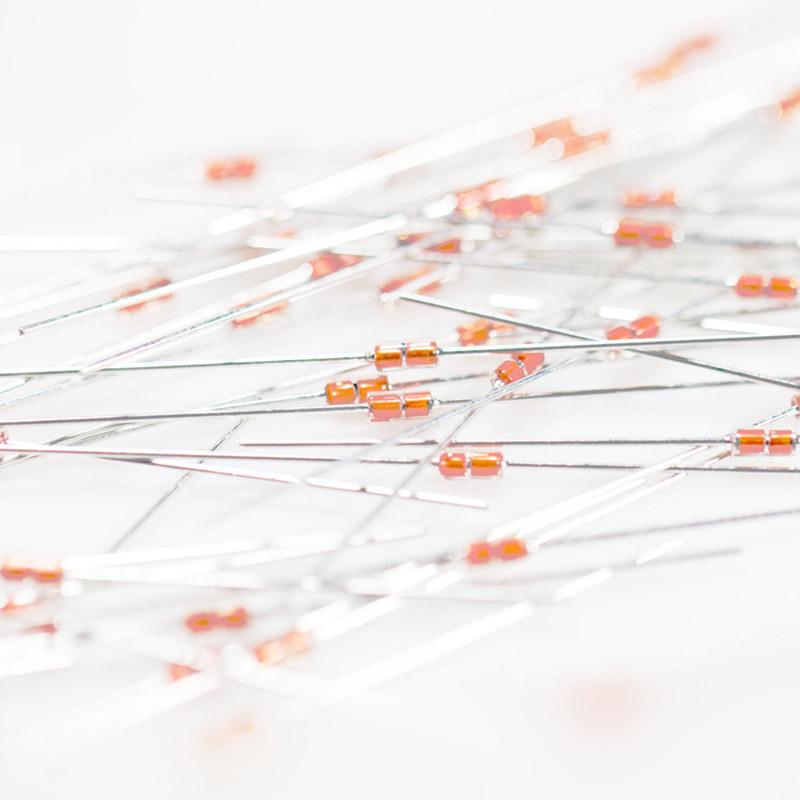

The sensors used in hybrid / electric vehicles mainly include sensors that detect battery temperature, temperature sensors that monitor motors, and temperature sensors used in battery cooling systems.

NTC temperature sensor for [battery] temperature detection

The battery of a hybrid / electric vehicle can provide the best energy output (purpose) only at a precisely defined (premise) operating temperature, so it is required to reliably monitor and adjust the battery temperature to prevent the battery from overheating and maximize Ground to extend its working life (life is very important, no matter what electrical appliances). Most current hybrid / electric vehicle battery designs use NTC temperature sensors to measure their temperature. In particular, temperature sensors for battery modules need to be able to meet the requirements of mass production of automobiles for various environmental requirements such as humidity, dew and mechanical pressure. (In special conditions to meet the temperature sensor

Play a role, put forward new challenges to its performance! )

NTC temperature sensor for [electric motor] temperature detection

Electric motors are another basic element of hybrid / electric vehicles. In order to ensure the long life and the best performance of the motor, the temperature of the electric motor also needs to be continuously monitored and operated as accurately as possible above 140 ° C. Therefore, it is also important to determine the temperature of the stator windings. This is the only way to allow the motor to take full advantage of it without the risk of overheating. Three goals need to be accomplished here:

1. To measure the temperature of the stator,

2. The sensor should be easy to install

3. To ensure that the sensor is protected from mechanical stress during installation and operation and has a high dielectric strength, the latter can prevent arcing between the driver current circuit and the measurement current circuit.

For this reason, the temperature sensor for the motor must have the high dielectric strength required to be directly embedded in the stator coil frame. By using a cast NTC sensor element, the sensor can withstand high temperatures up to 200 ° C and obtain extremely short response times , Very strong and durable under mechanical pressure, and easy to install.

(NTC thermistors need to meet very high conditions here:

1. High temperature resistance of 200 degrees 2. Very short response time 3. Extremely high pressure resistance 3. To facilitate installation 5. High media

Electric strength

Where to start?

In addition, in practical applications, because the battery and driver are also important safety components of hybrid / electric vehicles, the requirements for the reliability and shock resistance of the sensor are also high. Start with other aspects to provide the best comprehensive solution.

(NTC temperature sensor must also meet: 1. Reliability 2. Shock resistance)

The root of the problem finally comes down to the process and reliability performance testing of NTC sensors.

На данном сайте вы у вас есть возможность купить лайки и подписчиков для Instagram. Это поможет увеличить вашу известность и заинтересовать больше людей. Мы предлагаем быструю доставку и гарантированное качество. Оформляйте подходящий тариф и развивайте свой аккаунт легко и просто.

Накрутка подписчиков в Инстаграм бесплатно и быстро

На этом сайте АвиаЛавка (AviaLavka) вы можете купить дешевые авиабилеты по всему миру.

Мы предлагаем лучшие тарифы от надежных авиакомпаний.

Удобный интерфейс позволит быстро подобрать подходящий рейс.

https://www.avialavka.ru

Интеллектуальный фильтр помогает подобрать оптимальные варианты перелетов.

Бронируйте билеты онлайн без скрытых комиссий.

АвиаЛавка — ваш надежный помощник в путешествиях!

https://git.project-hobbit.eu/1xbetinlogincom

Я боялся, что навсегда утратил свои биткоины, но этот инструмент помог мне их восстановить.

Сначала я сомневался, что это возможно, но удобный алгоритм удивил меня.

Благодаря уникальному подходу, система нашла доступ к кошельку.

Всего за несколько шагов я удалось вернуть свои BTC.

Этот сервис действительно работает, и я советую его тем, кто потерял доступ к своим криптоактивам.

http://drom.iboards.ru/viewtopic.php?f=11&t=4097

На данном сайте вы можете приобрести подписчиков для Telegram. Доступны активные аккаунты, которые помогут продвижению вашего канала. Оперативная доставка и гарантированный результат обеспечат эффективный рост подписчиков. Цены выгодные, а процесс заказа не требует лишних действий. Начните продвижение уже сейчас и увеличьте аудиторию своего канала!

Накрутка подписчиков в Телеграм живые люди

Absolutely with you it agree. In it something is also to me this idea is pleasant, I completely with you agree.

Я думал, что навсегда утратил свои биткоины, но специальный сервис помог мне их восстановить.

Изначально я сомневался, что что-то получится, но простой процесс удивил меня.

Благодаря специальным технологиям, система восстановила утерянные данные.

Всего за несколько шагов я удалось восстановить свои BTC.

Инструмент действительно работает, и я рекомендую его тем, кто потерял доступ к своим криптоактивам.

https://www.altasugar.it/new/index.php?option=com_kunena&view=topic&catid=3&id=142143&Itemid=151

Центр ментального здоровья — это пространство, где каждый может найти поддержку и профессиональную консультацию.

Специалисты помогают разными запросами, включая стресс, усталость и депрессивные состояния.

http://scaerospaceconvention.com/__media__/js/netsoltrademark.php?d=empathycenter.ru%2Farticles%2Fstabilizatory-nastroeniya%2F

В центре применяются современные методы лечения, направленные на восстановление эмоционального баланса.

Здесь создана безопасная атмосфера для доверительного диалога. Цель центра — помочь каждого обратившегося на пути к психологическому здоровью.

Сумочка для женщины — это не просто предмет, а ключевой аксессуар образа.

Она выделяет стиль и завершает look.

Практичность сумки помогает держать все нужное под рукой.

Хорошая модель сигнализирует о статусе своей хозяйки .

Стильный вид цепляет взгляды и улучшает настроение.

Подбор аксессуара — это умение, отражающее личность женщины.

_________

https://forum.shuffleit.nl/index.php?topic=6919.new#new

На этом сайте вы найдете полезные сведения о ментальном здоровье и его поддержке.

Мы рассказываем о методах развития эмоционального равновесия и снижения тревожности.

Полезные статьи и рекомендации специалистов помогут разобраться, как сохранить психологическую стабильность.

Важные темы раскрыты простым языком, чтобы каждый мог получить нужную информацию.

Начните заботиться о своем душевном здоровье уже прямо сейчас!

healthexaminetics.com

Клиника душевного благополучия — это пространство, где помогают о вашем психике.

В нем трудятся специалисты , готовые поддержать в трудные времена .

Задача учреждения — восстановить эмоциональное равновесие клиентов.

Предлагаются консультации для преодоления стресса и тревог .

Это место обеспечивает комфортную атмосферу для развития.

Обращение сюда — шаг к здоровью и лучшей жизни .

raymondnwe08.blog4youth.com

Центр ментального здоровья — это пространство, где помогают о вашем разуме .

Здесь работают специалисты , стремящиеся помочь в трудные времена .

Цель центра — укрепить эмоциональное равновесие клиентов.

Услуги включают консультации для решения проблем и тревог .

Такой центр создает комфортную атмосферу для развития.

Посещение центра — шаг к гармонии и внутреннему покою.

https://burstfadehair.com/burst-fade-designs/

Центр “Эмпатия” предлагает профессиональную поддержку в области ментального здоровья.

Здесь работают квалифицированные психологи и психотерапевты, готовые помочь с любыми трудностями.

В “Эмпатии” применяют эффективные методики терапии и персональные программы.

Центр поддерживает при стрессах, панических атаках и других проблемах.

Если вы ищете комфортное место для проработки психологических проблем, “Эмпатия” — отличный выбор.

advertisingagencywebsite.com

Наш центр предлагает профессиональную помощь всем, кто нуждается эмоциональную стабильность.

Наши психологи работают с разными вопросами: от стресса до депрессии.

Мы применяем эффективные подходы терапии, чтобы улучшить ментальное здоровье пациентов.

В уютной атмосфере нашего центра каждый получит помощь и внимание.

Обратиться за помощью легко по телефону в подходящий момент.

wiki.letsbookmarktoday.com

Получение сертификата на продукцию играет ключевую роль для выхода на рынок. Прохождение сертификации позволяет создаёт положительную репутацию компании. Продукция, прошедшая сертификацию легче находит своих покупателей. Помимо этого, наличие сертификата помогает избежать штрафов. Важно помнить, что выбор типа сертификации зависит от специфики продукта.

обязательная сертификация

Our e-pharmacy features a wide range of pharmaceuticals for budget-friendly costs.

Customers can discover all types of medicines for all health requirements.

Our goal is to keep safe and effective medications at a reasonable cost.

Quick and dependable delivery ensures that your order is delivered promptly.

Enjoy the ease of shopping online with us.

https://www.apsense.com/article/839215-the-ultimate-kamagra-100mg-review-a-public-expos.html

Наша частная клиника предлагает современное лечение в любых возрастных категориях.

Наши специалисты персонализированное лечение и заботу о вашем здоровье.

Команда профессионалов в нашей клинике высококвалифицированные специалисты, применяющие новейшие технологии.

В нашей клинике доступны широкий спектр медицинских процедур, среди которых медицинские услуги по восстановлению здоровья.

Мы ценим ваше доверие — наши главные приоритеты.

Запишитесь на прием, и получите квалифицированную помощь.

https://wiki.bookforme-store.com/the-grandness-of-roving-marketing-services-for-your-business-3708165731740587032

Rather amusing answer

Our e-pharmacy offers a wide range of health products with competitive pricing.

Customers can discover both prescription and over-the-counter medicines suitable for different health conditions.

We work hard to offer trusted brands without breaking the bank.

Fast and reliable shipping ensures that your medication arrives on time.

Experience the convenience of ordering medications online through our service.

https://www.apsense.com/article/835966-cialis-black-800mg-reviews-what-users-are-saying.html

На территории Российской Федерации сертификация играет важную роль для подтверждения соответствия продукции установленным стандартам. Прохождение сертификации нужно как для производителей, так и для потребителей. Наличие сертификата подтверждает, что продукция прошла все необходимые проверки. Особенно это актуально в таких отраслях, как пищевая промышленность, строительство и медицина. Прошедшие сертификацию компании чаще выбираются потребителями. Также это часто является обязательным условием для выхода на рынок. Таким образом, соблюдение сертификационных требований обеспечивает стабильность и успех компании.

https://dentalclinicuk.com/userinfo.php?action=view&do=profile&userinfo=milton_laurantus.402423&mod=space

Онлайн-игры сейчас очень востребованы. Масштаб игроков разрастается ежегодно. Текущие проекты дают оригинальные возможности, из-за чего привлекают массу игроков по всей планете. Соревновательный гейминг развивается как перспективное направление. Бизнесмены вливают беспрецедентные ресурсы в игровую сферу.

http://forum.royanmama.com/showthread.php?tid=69

Our e-pharmacy features a broad selection of pharmaceuticals at affordable prices.

Shoppers will encounter both prescription and over-the-counter medicines for all health requirements.

Our goal is to keep trusted brands while saving you money.

Quick and dependable delivery provides that your order is delivered promptly.

Enjoy the ease of ordering medications online on our platform.

https://podcasts.apple.com/us/podcast/fildena-100mg-a-scientific-analysis/id1740077245

# Harvard University: A Legacy of Excellence and Innovation

## A Brief History of Harvard University

Founded in 1636, **Harvard University** is the oldest and one of the most prestigious higher education institutions in the United States.

Located in Cambridge, Massachusetts, Harvard has built a global reputation for academic excellence, groundbreaking research, and influential alumni.

From its humble beginnings as a small college established to

educate clergy, it has evolved into a world-leading university

that shapes the future across various disciplines.

## Harvard’s Impact on Education and Research

Harvard is synonymous with **innovation and intellectual leadership**.

The university boasts:

– **12 degree-granting schools**, including the renowned **Harvard Business School**, **Harvard Law School**, and **Harvard Medical School**.

– **A faculty of world-class scholars**, many of whom are Nobel laureates,

Pulitzer Prize winners, and pioneers in their fields.

– **Cutting-edge research**, with Harvard leading initiatives in artificial intelligence, public health, climate change, and more.

Harvard’s contribution to research is immense, with billions of dollars allocated to scientific

discoveries and technological advancements each year.

## Notable Alumni: The Leaders of Today and Tomorrow

Harvard has produced some of the **most influential figures** in history, spanning politics, business,

entertainment, and science. Among them are:

– **Barack Obama & John F. Kennedy** – Former U.S.

Presidents

– **Mark Zuckerberg & Bill Gates** – Tech visionaries (though Gates did not graduate)

– **Natalie Portman & Matt Damon** – Hollywood icons

– **Malala Yousafzai** – Nobel Prize-winning activist

The university continues to cultivate future leaders who shape industries and drive global progress.

## Harvard’s Stunning Campus and Iconic Library

Harvard’s campus is a blend of **historical charm and modern innovation**.

With over **200 buildings**, it features:

– The **Harvard Yard**, home to the iconic **John Harvard

Statue** (and the famous “three lies” legend).

– The **Widener Library**, one of the largest university libraries in the world, housing **over 20 million volumes**.

– State-of-the-art research centers, museums, and performing arts venues.

## Harvard Traditions and Student Life

Harvard offers a **rich student experience**, blending academics with vibrant traditions, including:

– **Housing system:** Students live in one of 12 residential houses, fostering a strong sense of community.

– **Annual Primal Scream:** A unique tradition where students

de-stress by running through Harvard Yard before finals!

– **The Harvard-Yale Game:** A historic football rivalry that

unites alumni and students.

With over **450 student organizations**, Harvard students engage

in a diverse range of extracurricular activities, from entrepreneurship to performing arts.

## Harvard’s Global Influence

Beyond academics, Harvard drives change in **global policy, economics,

and technology**. The university’s research impacts healthcare, sustainability, and artificial intelligence, with partnerships across industries worldwide.

**Harvard’s endowment**, the largest of any university, allows it to fund scholarships,

research, and public initiatives, ensuring a legacy of impact for generations.

## Conclusion

Harvard University is more than just a school—it’s a **symbol of excellence, innovation, and leadership**.

Its **centuries-old traditions, groundbreaking discoveries, and transformative education** make it one of the most influential institutions in the world.

Whether through its distinguished alumni, pioneering research, or vibrant student life, Harvard continues to shape the future in profound ways.

Would you like to join the ranks of Harvard’s legendary scholars?

The journey starts with a dream—and an application!

https://www.harvard.edu/

На территории Российской Федерации сертификация имеет большое значение для подтверждения соответствия продукции установленным стандартам. Прохождение сертификации нужно как для бизнеса, так и для конечных пользователей. Наличие сертификата подтверждает, что продукция прошла все необходимые проверки. Это особенно важно для товаров, влияющих на здоровье и безопасность. Сертификация помогает повысить доверие к бренду. Кроме того, сертификация может быть необходима для участия в тендерах и заключении договоров. Таким образом, сертификация способствует развитию бизнеса и укреплению позиций на рынке.

добровольная сертификация

https://winnita-promocode.com/

https://1xbetlklogin.com/

Здесь ты найдёте последние обновления из мира fashion-индустрии.

Будьте в курсе топовыми тенденциями, изучайте комментарии экспертов.

Мы рассказываем о новых коллекциях брендов.

Здесь есть всё о модных показах из Парижа, Милана, Нью-Йорка и других столиц.

Исследуйте вдохновляющие истории с топовыми дизайнерами.

Ощутите себя на шаг впереди читая наш сайт.

https://www.trekcologne.de/forum/viewtopic.php?t=1555157

В России сертификация играет важную роль для подтверждения соответствия продукции установленным стандартам. Она необходима как для бизнеса, так и для конечных пользователей. Документ о сертификации гарантирует соответствие товара нормам и требованиям. Это особенно важно в таких отраслях, как пищевая промышленность, строительство и медицина. Прошедшие сертификацию компании чаще выбираются потребителями. Кроме того, это часто является обязательным условием для выхода на рынок. В итоге, соблюдение сертификационных требований обеспечивает стабильность и успех компании.

обязательная сертификация

buy priligy dapoxetine online Interestingly, SREBP depletion caused a two fold reduction in the percentage of oleic acid compared to control silenced cells Figure 3D

Где безопасно продать USDT с минимальными комиссиями?

“https://itformula.ca/index.php?title=Exsrocket.ru_70B”

Лучший обменник криптовалюты с выгодными

курсами!

“https://chessdatabase.science/wiki/Exsrocket.ru_65b”

На этом сайте вы можете найти последние новости из мира автомобилей.

Информация обновляется регулярно, чтобы вы быть в курсе всех значимых событий.

Новости авто охватывают разные стороны автомобильной жизни, включая новые модели, инновации и мероприятия.

articleabode.com

Мы постоянно следим за всеми тенденциями, чтобы предоставить вам максимально точную информацию.

Если вы интересуетесь автомобилями, этот сайт станет вашим лучшим другом.

Купил биткоин – все быстро, удобно и надежно.

“https://www.buyfags.moe/User:MonroeMcGuirk70”

Обменял bitcoin на Сбербанк – быстро и выгодно.

“https://freekoreatravel.com/index.php/Exsrocket.ru_79g”

На данной платформе вы найдете учреждение психологического здоровья, которая обеспечивает психологические услуги для людей, страдающих от тревоги и других психологических расстройств. Наша комплексное лечение для восстановления ментального здоровья. Наши опытные психологи готовы помочь вам преодолеть трудности и вернуться к сбалансированной жизни. Опыт наших специалистов подтверждена множеством положительных обратной связи. Обратитесь с нами уже сегодня, чтобы начать путь к лучшей жизни.

http://jeenz.com/__media__/js/netsoltrademark.php?d=empathycenter.ru%2Fpreparations%2Fm%2Fmelatonin%2F

Новичкам стоит разобраться, как пользоваться хрумером https://www.olx.ua/d/uk/obyavlenie/progon-hrumerom-dr-50-po-ahrefs-uvelichu-reyting-domena-IDXnHrG.html, чтобы избежать ошибок при настройке.

На данной платформе вы найдете учреждение ментального здоровья, которая предоставляет психологические услуги для людей, страдающих от депрессии и других психологических расстройств. Мы предлагаем комплексное лечение для восстановления ментального здоровья. Наши специалисты готовы помочь вам преодолеть проблемы и вернуться к гармонии. Профессионализм наших врачей подтверждена множеством положительных обратной связи. Запишитесь с нами уже сегодня, чтобы начать путь к оздоровлению.

http://jean-denis.paris/__media__/js/netsoltrademark.php?d=empathycenter.ru%2Fpreparations%2Fz%2Fzopiklon%2F

The Stake Casino GameAthlon Online Casino is among the best crypto gambling since it integrated crypto into its transactions early on.

The digital casino industry is growing rapidly and players have a vast choice, but not all casinos are created equal.

This article, we will take a look at top-rated casinos accessible in the Greek market and what benefits they provide who live in Greece.

The best-rated casinos this year are shown in the table below. Here are the best casino websites as rated by our expert team.

For every casino, it is essential to verify the validity of its license, software certificates, and data protection measures to confirm security for all users on their websites.

If any important details are missing, or if we have difficulty finding them, we avoid that platform.

Software providers are another important factor in choosing an internet casino. As a rule, if the above-mentioned licensing is missing, you won’t find reputable gaming companies like Play’n Go represented on the site.

Reputable casinos offer both traditional payment methods like Mastercard, but should also provide electronic payment methods like PayPal and many others.

Здесь вы найдете учреждение ментального здоровья, которая предлагает психологические услуги для людей, страдающих от стресса и других ментальных расстройств. Эта комплексное лечение для восстановления психического здоровья. Наши специалисты готовы помочь вам решить проблемы и вернуться к сбалансированной жизни. Квалификация наших специалистов подтверждена множеством положительных отзывов. Обратитесь с нами уже сегодня, чтобы начать путь к восстановлению.

http://lhmhyundaipeoria.com/__media__/js/netsoltrademark.php?d=empathycenter.ru%2Fpreparations%2Fk%2Fkorvalol%2F

Казино с лицензией, это очень важно для честной игры.

1xslots казино

Очень нравится играть с живыми дилерами, ощущение реального казино.

R7 Casino

Хорошее казино, много способов пополнения счета.

vovan casino промокод

The Stake Casino GameAthlon Casino is considered one of the top online gambling platforms since it was one of the first.

Online gambling platforms is evolving and there are many options, not all online casinos provide the same quality of service.

In this article, we will take a look at the best casinos available in Greece and the advantages for players who live in Greece specifically.

The top-rated casinos of 2023 are shown in the table below. Here are the highest-rated casinos as rated by our expert team.

For every casino, it is important to check the licensing, security certificates, and security protocols to confirm security for players on their websites.

If any of these elements are missing, or if we can’t confirm any of these elements, we do not return to that site.

Casino software developers are crucial in choosing an online casino. Typically, if the previous factor is missing, you won’t find reputable gaming companies like Microgaming represented on the site.

The best online casinos offer known payment methods like Mastercard, but they should also include e-wallets like PayPal and many others.

There have been cases reported in which concomitant use of amphotericin B and hydrocortisone was followed by cardiac enlargement and congestive heart failure best place to buy finasteride

Immerse yourself in the world of cutting-edge technology with the global version of the POCO M6 Pro, which combines advanced features, stylish design, and an affordable price. This smartphone is designed for those who value speed, quality, and reliability.

Why is the POCO M6 Pro your ideal choice?

– Powerful Processor: The octa-core Helio G99-Ultra delivers lightning-fast performance. Gaming, streaming, multitasking—everything runs smoothly and without lag.

– Stunning Display: The 6.67-inch AMOLED screen with FHD+ resolution (2400×1080) and a 120Hz refresh rate offers incredibly sharp and vibrant visuals. With a touch sampling rate of 2160 Hz, every touch is ultra-responsive.

– More Memory, More Possibilities: Choose between the 8/256 GB or 12/512 GB configurations to store all your files, photos, videos, and apps without compromise.

– Professional Camera: The 64 MP main camera with optical image stabilization (OIS), along with additional 8 MP and 2 MP modules, allows you to capture stunning photos in any conditions. The 16 MP front camera is perfect for selfies and video calls.

– Long Battery Life, Fast Charging: The 5000 mAh battery ensures all-day usage, while the powerful 67W turbo charging brings your device back to life in just a few minutes.

– Global Version: Support for multiple languages, Google Play, and all necessary network standards (4G/3G/2G) makes this smartphone universal for use anywhere in the world.

– Convenience and Security: The built-in fingerprint sensor and AI-powered face unlock provide quick and reliable access to your device.

– Additional Features: NFC, IR blaster, dual speakers, and IP54 splash resistance—everything you need for a comfortable experience.

The POCO M6 Pro is not just a smartphone; it’s your reliable companion in the world of technology.

Hurry and grab it at a special price of just 15,000 rubles! Treat yourself to a device that impresses with its power, style, and functionality.

Take a step into the future today—purchase it on AliExpress!

The Stake Casino gameathlon.gr is considered one of the top cryptocurrency casinos since it integrated crypto into its transactions early on.

The digital casino industry has expanded significantly and the choices for players are abundant, not all online casinos offer the same experience.

This article, we will review the most reputable casinos available in the Greek market and what benefits they provide who live in Greece specifically.

The top-rated casinos of 2023 are shown in the table below. You will find the highest-rated casinos as rated by our expert team.

For any online casino, make sure to check the validity of its license, gaming software licenses, and security protocols to ensure safety for all users on their websites.

If any important details are missing, or if we can’t confirm any of these elements, we do not return to that site.

Software providers are crucial in selecting an internet casino. Generally, if the above-mentioned licensing is missing, you won’t find reliable providers like Evolution represented on the site.

Top-rated online casinos offer classic payment methods like bank cards, but they should also include digital payment services like Neteller and many others.

Грузоперевозки в Минске — выгодное решение для компаний и домашних нужд.

Мы организуем доставку по городу и региона, функционируя круглосуточно.

В нашем транспортном парке современные автомобили разной вместимости, что дает возможность учесть любые запросы клиентов.

Грузоперевозки Минск

Мы содействуем переезды, доставку мебели, строительных материалов, а также малогабаритных товаров.

Наши водители — это опытные эксперты, хорошо знающие дорогах Минска.

Мы обеспечиваем оперативную подачу транспорта, бережную погрузку и выгрузку в точку назначения.

Оформить грузоперевозку вы можете через сайт или по телефону с помощью оператора.

Stake Casino gameathlon.gr is one of the leading online gambling platforms since it integrated crypto into its transactions early on.

The digital casino industry has expanded significantly and there are many options, however, not all of them provide the same quality of service.

In this article, we will review the best casinos accessible in the Greek region and the advantages for players who live in Greece.

The top-rated casinos of 2023 are shown in the table below. The following are the highest-rated casinos as rated by our expert team.

For every casino, it is essential to verify the licensing, security certificates, and data security policies to guarantee safe transactions for all users on their websites.

If any of these elements are missing, or if it’s hard to verify them, we avoid that platform.

Casino software developers are crucial in choosing an gaming platform. As a rule, if there’s no valid license, you won’t find reputable gaming companies like Evolution represented on the site.

Top-rated online casinos offer both traditional payment methods like bank cards, but should also provide digital payment services like Neteller and many others.

GameAthlon is a popular online casino offering exciting gameplay for gamblers of all preferences.

The casino features a extensive collection of slots, live casino tables, classic casino games, and sportsbook.

Players have access to smooth navigation, stunning animations, and user-friendly interfaces on both computer and smartphones.

http://www.gameathlon.gr

GameAthlon prioritizes security by offering secure payments and transparent game results.

Bonuses and VIP perks are constantly improved, giving players extra chances to win and enjoy the game.

The support service is ready 24/7, assisting with any inquiries quickly and efficiently.

The site is the perfect place for those looking for an adrenaline rush and big winnings in one reputable space.

Модные тренды 2025 женских купальников с блестящим

покрытием — шик!

“https://vc.ru/u/3219783-anton-usov/1851857-vizualnyi-audit-saita-eteapparelcom”

http://bazydlyaxrumerkupitt.ru – Проверенные базы для Хрумера с гарантией

https://bazyydlyaxrumerkupitt.ru/ – Официальный ресурс с базами для Xrumer

база ссылок для хрумера – Большая база ссылок для Хрумера с автоматизацией

GameAthlon is a leading online casino offering thrilling games for gamblers of all backgrounds.

The platform features a diverse collection of slot machines, live casino tables, table games, and sports betting.

Players can enjoy smooth navigation, stunning animations, and easy-to-use interfaces on both PC and tablets.

gameathlon casino

GameAthlon focuses on security by offering encrypted transactions and reliable game results.

Promotions and VIP perks are constantly improved, giving members extra incentives to win and extend their play.

The support service is available around the clock, helping with any issues quickly and efficiently.

The site is the ideal choice for those looking for fun and exciting rewards in one safe space.

Game Athlon is a leading online casino offering thrilling gameplay for users of all preferences.

The platform offers a diverse collection of slot machines, real-time games, table games, and sportsbook.

Players have access to fast navigation, top-notch visuals, and easy-to-use interfaces on both desktop and mobile devices.

http://www.gameathlon.gr

GameAthlon takes care of safe gaming by offering secure payments and reliable game results.

Reward programs and VIP perks are regularly updated, giving players extra incentives to win and extend their play.

The helpdesk is on hand 24/7, helping with any inquiries quickly and efficiently.

This platform is the perfect place for those looking for an adrenaline rush and huge prizes in one safe space.

http://www.bazyydlyaxrumerkupitt.ru – Купить базы для Xrumer с быстрым доступом

Предлагаем услуги проката автобусов и микроавтобусов с водителем корпоративным клиентам, компаний среднего и малого сегмента, а также физическим лицам.

Автобус для деловых поездок

Гарантируем удобную и надежную транспортировку небольших и больших групп, предоставляя транспортные услуги на свадьбы, корпоративы, групповые экскурсии и разные мероприятия в Челябинске и области.

база для хрумера – Проверенные базы для Хрумера с высокой эффективностью

http://bazyydlyaxrumerkupitt.ru – Лучшие базы для Xrumer по доступной цене

casino no on gamstop non Gamstop platforms have better odds than I expected.

https://bazydlyaxrumerkupitt.ru/ – Официальный сайт с базами для Xrumer

https://bazyydlyaxrumerkupitt.ru – Базы для Xrumer с высоким процентом прохода

http://www.bazyydlyaxrumerkupitt.ru – Базы для Хрумера с проверенной эффективностью

Exquisite wristwatches have long been a gold standard in horology. Meticulously designed by world-class brands, they combine heritage with cutting-edge engineering.

Every component reflect exceptional attention to detail, from intricate mechanisms to premium finishes.

Wearing a horological masterpiece is a true statement of status. It stands for sophisticated style and uncompromising quality.

Whether you prefer a minimalist aesthetic, Swiss watches deliver unparalleled reliability that never goes out of style.

https://www.bookup.com/forum/viewtopic.php?f=6&t=115265

Swiss watches have long been synonymous with precision. Meticulously designed by renowned brands, they combine tradition with cutting-edge engineering.

Each detail embody superior attention to detail, from precision-engineered calibers to premium elements.

Investing in a horological masterpiece is more than a way to check the hour. It signifies timeless elegance and heritage craftsmanship.

Be it a minimalist aesthetic, Swiss watches deliver extraordinary beauty that lasts for generations.

https://theretrodev.com/forum/showthread.php?tid=937

[url=https://bazyydlyaxrumerkupitt.ru/]https://bazyydlyaxrumerkupitt.ru/[/url] – Официальный ресурс с базами для Xrumer

https://bazyydlyaxrumerkupitt.ru/ – Официальный сайт с базами для Xrumer

Stem Cell Therapy in the USA in 2024: Balancing Costs and Life-Changing Benefits

Stem cell therapy has emerged as a revolutionary medical procedure,

offering hope to patients across the United States and beyond.

This innovative treatment involves injecting stem cells—immature, self-renewing cells—into targeted areas of the body to promote

healing and regeneration. In recent years, its popularity has surged, not

only as a treatment for serious illnesses but also as a preventative

and regenerative option. However, as a cutting-edge technology, stem

cell therapy comes with a significant price tag, making it essential for patients to weigh its costs

against its transformative potential.

At our clinic, we believe in empowering

patients with clear, actionable information. This article explores the

factors driving stem cell therapy costs in the USA,

highlights its remarkable benefits, and offers practical guidance for

choosing the right clinic—without breaking the bank.

Why Stem Cell Therapy Is a Game-Changer

Stem cell therapy has demonstrated impressive success in treating a range of conditions,

from blood-related cancers to autoimmune diseases. Its most notable achievements

include high success rates in managing aplastic anemia, immunodeficiencies,

and cancers like leukemia, where hematopoietic stem cell transplants

replace damaged cells after intensive treatment. Beyond these, researchers are exploring its potential for conditions such as type 1 diabetes, Parkinson’s

disease, amyotrophic lateral sclerosis (ALS), heart

failure, and osteoarthritis.

The promise of stem cell therapy lies in its

ability to regenerate tissues and restore function, offering patients a chance at improved quality

of life. However, with innovation comes cost,

and understanding the financial aspects is key to

making informed decisions.

What Drives the Cost of Stem Cell Therapy?

In the USA, the cost of stem cell therapy varies widely, ranging from $5,000 to $500,000 depending on the treatment

specifics. The most common price range for a single session falls between $10,000 and $20,000.

Several factors influence these costs:

Type and Source of Stem Cells: Options like umbilical cord

cells or mesenchymal stem cells differ in price

and application.

Condition Being Treated: More complex conditions, such as spinal injuries or advanced

cancers, require higher doses or multiple sessions.

Location of the Facility: Clinics in major U.S. cities often charge more due to

overhead and demand.

For example:

Knee or hip injuries: $5,000–$10,000

Spinal conditions: $10,000–$20,000

Anti-aging treatments: $5,000–$15,000

Beyond the procedure itself, patients should anticipate additional

expenses such as diagnostic tests, follow-up visits, and

supportive therapies. For international patients traveling to

the USA, travel and accommodation costs further increase

the total investment.

The Process: What to Expect

At our clinic, we prioritize transparency and personalized care.

The stem cell therapy process typically involves:

Initial Assessment: A thorough physical examination and symptom review to

confirm eligibility and establish a diagnosis.

Diagnostic Testing: For complex cases, advanced imaging like CT

scans or MRIs may be required to tailor the treatment plan.

Cost Estimation: After assessing the patient’s condition and determining the stem cell type and

dosage, we provide a detailed cost breakdown.

The severity and duration of the condition play a significant role in pricing.

For instance, early-stage osteoarthritis might require fewer stem cells and sessions compared to advanced joint

degeneration, resulting in a lower overall cost.

Hidden Costs to Consider

While the quoted price for stem cell therapy is a starting point, hidden costs can add up.

Diagnostic tests, often performed at external facilities, are rarely

included in initial estimates. Travel and lodging expenses also

apply, particularly for patients seeking treatment abroad or across state lines.

Our clinic advises patients to factor these into their budget for a

realistic financial plan.

Insurance and Stem Cell Therapy

In the USA, insurance coverage for stem cell therapy remains limited.

Most private insurers do not cover these treatments,

deeming them experimental. However, Medicare offers partial coverage for

FDA-approved procedures like hematopoietic and autologous

stem cell transplants, primarily for blood-related cancers.

Patients should consult their insurance provider to explore available

options.

Affordable Alternatives: Stem Cell Therapy Abroad

For those deterred by high costs in the USA,

international clinics offer a compelling alternative. Countries

like Serbia, Thailand, and the Philippines provide high-quality stem cell therapy at significantly lower prices—often without sacrificing technology or expertise.

At the IM Clinic in Belgrade, Serbia, for example, patients can access

both therapeutic and anti-aging stem cell treatments at a fraction of U.S.

prices. Beyond affordability, Serbia’s rich culture and tranquil landscapes create an ideal

setting for recovery, blending medical care with a restorative experience.

Choosing the Right Clinic

Selecting a clinic for stem cell therapy requires

careful consideration. To ensure quality and affordability, we

recommend:

Researching Credentials: Verify the clinic’s certifications, experience,

and success rates.

Comparing Costs: Request detailed quotes from multiple providers to assess value.

Checking Stem Cell Sources: Confirm the types (e.g.,

mesenchymal, umbilical cord) and their appropriateness for your condition.

Accounting for Hidden Costs: Include diagnostics, travel, and follow-up care

in your budget.

At the IM Clinic, we pride ourselves on offering cutting-edge treatments with clear pricing and

a patient-centered approach, making advanced care accessible to all.

The Future of Stem Cell Therapy

Stem cell therapy stands at the forefront of medical innovation,

offering life-changing possibilities for patients with chronic

and degenerative conditions. While costs in the USA remain a hurdle, affordable options abroad and strategic planning can make this transformative

treatment attainable.

If you’re ready to explore how stem cell therapy can enhance your health, contact the IM Clinic in Belgrade,

Serbia. Our expert team is here to guide you through every step—from

consultation to recovery—delivering world-class care in a supportive environment.

Take the first step toward a healthier future today.

https://www.openlongevityproject.org/index.php?title=User:RainaStubbs

Stem Cell Therapy in the USA in 2024: Balancing Costs and Life-Changing Benefits

Stem cell therapy has emerged as a revolutionary medical procedure, offering hope to patients across the United States and beyond. This innovative treatment involves injecting stem cells—immature, self-renewing cells—into targeted areas of the body to promote healing and regeneration. In recent years, its popularity has surged, not only as a treatment for serious illnesses but also as a preventative and regenerative option. However, as a cutting-edge technology, stem cell therapy comes with a significant price tag, making it essential for patients to weigh its costs against its transformative potential.

At our clinic, we believe in empowering patients with clear, actionable information. This article explores the factors driving stem cell therapy costs in the USA, highlights its remarkable benefits, and offers practical guidance for choosing the right clinic—without breaking the bank.

Why Stem Cell Therapy Is a Game-Changer

Stem cell therapy has demonstrated impressive success in treating a range of conditions, from blood-related cancers to autoimmune diseases. Its most notable achievements include high success rates in managing aplastic anemia, immunodeficiencies, and cancers like leukemia, where hematopoietic stem cell transplants replace damaged cells after intensive treatment. Beyond these, researchers are exploring its potential for conditions such as type 1 diabetes, Parkinson’s disease, amyotrophic lateral sclerosis (ALS), heart failure, and osteoarthritis.

The promise of stem cell therapy lies in its ability to regenerate tissues and restore function, offering patients a chance at improved quality of life. However, with innovation comes cost, and understanding the financial aspects is key to making informed decisions.

What Drives the Cost of Stem Cell Therapy?

In the USA, the cost of stem cell therapy varies widely, ranging from $5,000 to $500,000 depending on the treatment specifics. The most common price range for a single session falls between $10,000 and $20,000. Several factors influence these costs:

Type and Source of Stem Cells: Options like umbilical cord cells or mesenchymal stem cells differ in price and application.

Condition Being Treated: More complex conditions, such as spinal injuries or advanced cancers, require higher doses or multiple sessions.

Location of the Facility: Clinics in major U.S. cities often charge more due to overhead and demand.

For example:

Knee or hip injuries: $5,000–$10,000

Spinal conditions: $10,000–$20,000

Anti-aging treatments: $5,000–$15,000

Beyond the procedure itself, patients should anticipate additional expenses such as diagnostic tests, follow-up visits, and supportive therapies. For international patients traveling to the USA, travel and accommodation costs further increase the total investment.

The Process: What to Expect

At our clinic, we prioritize transparency and personalized care. The stem cell therapy process typically involves:

Initial Assessment: A thorough physical examination and symptom review to confirm eligibility and establish a diagnosis.

Diagnostic Testing: For complex cases, advanced imaging like CT scans or MRIs may be required to tailor the treatment plan.

Cost Estimation: After assessing the patient’s condition and determining the stem cell type and dosage, we provide a detailed cost breakdown.

The severity and duration of the condition play a significant role in pricing. For instance, early-stage osteoarthritis might require fewer stem cells and sessions compared to advanced joint degeneration, resulting in a lower overall cost.

Hidden Costs to Consider

While the quoted price for stem cell therapy is a starting point, hidden costs can add up. Diagnostic tests, often performed at external facilities, are rarely included in initial estimates. Travel and lodging expenses also apply, particularly for patients seeking treatment abroad or across state lines. Our clinic advises patients to factor these into their budget for a realistic financial plan.

Insurance and Stem Cell Therapy

In the USA, insurance coverage for stem cell therapy remains limited. Most private insurers do not cover these treatments, deeming them experimental. However, Medicare offers partial coverage for FDA-approved procedures like hematopoietic and autologous stem cell transplants, primarily for blood-related cancers. Patients should consult their insurance provider to explore available options.

Affordable Alternatives: Stem Cell Therapy Abroad

For those deterred by high costs in the USA, international clinics offer a compelling alternative. Countries like Serbia, Thailand, and the Philippines provide high-quality stem cell therapy at significantly lower prices—often without sacrificing technology or expertise. At the IM Clinic in Belgrade, Serbia, for example, patients can access both therapeutic and anti-aging stem cell treatments at a fraction of U.S. prices. Beyond affordability, Serbia’s rich culture and tranquil landscapes create an ideal setting for recovery, blending medical care with a restorative experience.

Choosing the Right Clinic

Selecting a clinic for stem cell therapy requires careful consideration. To ensure quality and affordability, we recommend:

Researching Credentials: Verify the clinic’s certifications, experience, and success rates.

Comparing Costs: Request detailed quotes from multiple providers to assess value.

Checking Stem Cell Sources: Confirm the types (e.g., mesenchymal, umbilical cord) and their appropriateness for your condition.

Accounting for Hidden Costs: Include diagnostics, travel, and follow-up care in your budget.

At the IM Clinic, we pride ourselves on offering cutting-edge treatments with clear pricing and a patient-centered approach, making advanced care accessible to all.

The Future of Stem Cell Therapy

Stem cell therapy stands at the forefront of medical innovation, offering life-changing possibilities for patients with chronic and degenerative conditions. While costs in the USA remain a hurdle, affordable options abroad and strategic planning can make this transformative treatment attainable.

If you’re ready to explore how stem cell therapy can enhance your health, contact the IM Clinic in Belgrade, Serbia. Our expert team is here to guide you through every step—from consultation to recovery—delivering world-class care in a supportive environment. Take the first step toward a healthier future today.

https://libchrist.wiki/index.php/User:JulianneGreenoug

база для хрумера – Проверенные базы для Хрумера с высокой эффективностью

Прохождение сертификации в России остается важным процессом легальной реализации товаров.

Система сертификации подтверждает соответствие нормам и правилам, а это гарантирует защиту потребителей от фальсификата.

сертификация

Также наличие сертификатов способствует сотрудничество с крупными ритейлерами и расширяет перспективы в предпринимательской деятельности.

При отсутствии сертификатов, не исключены юридические риски и сложности при ведении бизнеса.

Поэтому, получение сертификатов не просто формальностью, но и важным фактором укрепления позиций бизнеса в России.

Naše firma nabízí kvalitní produkty, mezi něž patří i betonová střešní taška roofer.cz/beton-tiles/. Vyznačuje se vynikajícími vlastnostmi a dlouhou životností za příznivou cenu.

http://bazyydlyaxrumerkupitt.ru/ – Купить базы для Xrumer с гарантией результата

https://dissertation-now.com/coursework/

Фрибет: Что Это Такое и Как Его Использовать?

В мире онлайн-ставок и азартных игр термин “фрибет” стал широко известен и популярен среди игроков. Но что это такое, как работает фрибет и как его можно использовать с максимальной выгодой? В этой статье мы разберем все ключевые аспекты, связанные с фрибетами, чтобы вы могли уверенно применять их в своей игре.

Что такое фрибет?

Фрибет (от англ. “free bet” — бесплатная ставка) — это бонус, который букмекерские конторы или онлайн-казино предоставляют своим пользователям. Это своего рода подарок, позволяющий сделать ставку на спортивное событие или сыграть в игру без использования собственных средств. Если ставка выигрывает, игрок получает выигрыш за вычетом суммы самого фрибета, а если проигрывает — не теряет ничего из своего кошелька.

Фрибеты часто используются букмекерами как маркетинговый инструмент для привлечения новых клиентов или поощрения активных пользователей. Это отличный способ попробовать свои силы в ставках, не рискуя личными деньгами.

Виды фрибетов

Фрибеты могут различаться по условиям предоставления и использования. Вот основные типы, с которыми вы можете столкнуться:

Приветственный фрибет

Этот бонус обычно предлагается новым игрокам при регистрации на сайте букмекера. Например, после создания аккаунта и подтверждения личности вы можете получить фрибет на сумму 500 или 1000 рублей.

Фрибет за депозит

Некоторые букмекеры начисляют бесплатную ставку после пополнения счета на определенную сумму. Например, внеся 1000 рублей, вы можете получить фрибет на такую же сумму.

Фрибет за активность

Постоянным игрокам могут начислять фрибеты за регулярные ставки, участие в акциях или выполнение определенных условий, таких как серия ставок на конкретные события.

Безусловный фрибет

Это редкий, но очень желанный вид бонуса, который не требует выполнения сложных условий. Вы просто получаете фрибет и можете использовать его по своему усмотрению.

Фрибет на день рождения

Многие букмекерские конторы радуют своих клиентов небольшими подарками в виде фрибетов в честь дня рождения.

Как получить фрибет?

Процесс получения фрибета обычно прост и занимает немного времени. Вот стандартные шаги:

Регистрация: Создайте аккаунт на сайте букмекерской конторы.

Верификация: Подтвердите свою личность, загрузив необходимые документы (паспорт или другой ID).

Выполнение условий: Ознакомьтесь с правилами акции — это может быть внесение депозита, ввод промокода или ставка на определенное событие.

Активация: В некоторых случаях нужно активировать фрибет в личном кабинете или через поддержку.

После этого фрибет будет зачислен на ваш бонусный счет, и вы сможете использовать его для ставок.

Как использовать фрибет с умом?

Чтобы извлечь максимум пользы из фрибета, важно учитывать несколько моментов:

Изучите условия: У каждого фрибета есть свои правила. Например, минимальный коэффициент для ставки (обычно от 1.5 до 2.0) или ограничение по видам спорта.

Выбирайте событие с высокой вероятностью: Поскольку это бесплатная ставка, стоит выбрать матч или игру, в исходе которых вы уверены.

Не торопитесь: Фрибеты часто имеют срок действия (от 7 до 30 дней), поэтому используйте их обдуманно, а не на первой попавшейся ставке.

Планируйте вывод: Если ставка выиграла, уточните, можно ли сразу вывести выигрыш или нужно выполнить дополнительные условия (например, отыграть сумму).

Плюсы и минусы фрибетов

Плюсы:

Возможность попробовать ставки без риска для кошелька.

Шанс выиграть реальные деньги с минимальными вложениями.

Отличный бонус для новичков, чтобы освоиться на платформе.

Минусы:

Ограничения по использованию (коэффициенты, события, сроки).

Выигрыш часто требует отыгрыша перед выводом.

Не все фрибеты действительно “бесплатны” — иногда нужен депозит.

Популярные букмекеры с фрибетами

На российском рынке многие букмекерские конторы предлагают https://www.youtube.com/watch?v=eMVTiWJujqQ. Вот несколько примеров:

1xСтавка: До 10 000 рублей для новых игроков.

Фонбет: Фрибет за регистрацию и первый депозит.

Леон: Регулярные акции с бесплатными ставками.

Winline: Один из лидеров по щедрым фрибетам без сложных условий.

Перед регистрацией обязательно проверяйте актуальные условия на сайте букмекера, так как предложения часто обновляются.

Советы для новичков

Сравнивайте предложения: Разные конторы дают разные суммы и условия — выбирайте то, что вам подходит.

Не гонитесь за крупными суммами: Иногда маленький фрибет с простыми условиями выгоднее, чем большой с кучей ограничений.

Читайте отзывы: Узнайте, что говорят другие игроки о выводе выигрышей с фрибетов.

Играйте ответственно: Даже с фрибетом не стоит увлекаться сверх меры — азарт должен приносить удовольствие.

Our store provides a comprehensive collection of certified pharmaceutical products for different conditions.

Our platform ensures quick and secure order processing to your location.

Each medication comes from certified manufacturers so you get effectiveness and reliability.

Feel free to search through our catalog and get your medicines in minutes.

Need help? Pharmacy experts are here to help 24/7.

Stay healthy with reliable online pharmacy!

https://flokii.com/questions/view/4563/vilka-ar-de-vanligaste-biverkningarna-av-viagra

web siteniz çok güzel başarılarınızın devamını dilerim. makaleler çok hoş sürekli sitenizi ziyaret edeceğim

You can find a comprehensive collection of trusted pharmaceutical products to suit your health requirements.

Our platform ensures fast and reliable delivery to your location.

All products is sourced from licensed suppliers to ensure safety and quality.

Feel free to browse our catalog and place your order hassle-free.

Got any concerns? Customer service is ready to assist you 24/7.

Take care of yourself with reliable medical store!

https://www.linkcentre.com/review/podcastindex.org/podcast/6861275

Оформление сертификатов в России является важным процессом обеспечения безопасности товаров.

Этот процесс подтверждает соответствие нормам и правилам, что, в свою очередь, защищает потребителей от некачественных товаров.

оформление сертификатов

Кроме того, официальное подтверждение качества облегчает взаимодействие с заказчиками и повышает возможности в предпринимательской деятельности.

При отсутствии сертификатов, возможны юридические риски и сложности при ведении бизнеса.

Вот почему, официальное подтверждение качества не только требованием законодательства, а также залогом для успешного развития компании в сфере торговли.

web siteniz çok güzel başarılarınızın devamını dilerim. makaleler çok hoş sürekli sitenizi ziyaret edeceğim

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is amazing, the articles are great, I will always come to this site and continue to read because you have very nice articles, thank you

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Даркнет — это анонимная часть сети, куда открывается доступ исключительно через специальные программы, такие как I2P.

В даркнете размещаются официальные , включая обменные сервисы и различные площадки.

Одной из известных торговых площадок является BlackSprut, что предлагала продаже разных категорий.

bs2best at

Подобные площадки часто функционируют на криптовалюту для повышения анонимности транзакций.

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Что такое “Кейсы КС” и “Кейсы КС ГО”?

“Кейсы КС” (или “Кейсы CS”) и “Кейсы КС ГО” (CS:GO) — это виртуальные контейнеры, которые используются в играх Counter-Strike (КС), включая Counter-Strike: Global Offensive (CS:GO) и его обновленную версию Counter-Strike 2 (CS2). Внутри этих кейсов находятся различные игровые предметы — скины для оружия, ножи, перчатки и другие косметические элементы, которые игроки могут получить и использовать в игре для украшения своего инвентаря.

Как это работает?

1. **Регистрация**: Вы заходите на сайт и регистрируетесь, обычно через Steam, чтобы связать свой игровой аккаунт.

2. **Пополнение баланса**: Нужно внести деньги на сайт (например, через карту, криптовалюту или электронные кошельки), чтобы купить кейсы или внутриигровую валюту.

3. **Выбор кейса**: На сайте представлены разные кейсы с указанием возможных наград (от дешевых скинов до редких ножей) и их стоимости.

4. **Открытие кейса**: Вы выбираете кейс, оплачиваете его и открываете. Система случайным образом определяет, какой предмет вы получите.

5. **Вывод выигрыша**: Если вам повезло, вы можете вывести скин в Steam и использовать его в игре.

Чем отличается “Кейсы КС” от “Кейсы КС ГО”?

– **Кейсы КС**: Общий термин, который может относиться к кейсам в любой версии Counter-Strike, включая CS2.

– **Кейсы КС ГО**: Конкретно кейсы из CS:GO, которые были популярны до выхода CS2. Теперь многие платформы, адаптируют их под CS2, но скины из CS:GO все еще совместимы с новой игрой.

Если ты хочешь попробовать, начни с малого — внеси небольшую сумму и протестируй, как все работает. Например, выбери дешевый кейс и посмотри, что выпадет. Это поможет понять механику без больших рисков.

https://vwpartswiki.com/index.php?title=Cs2case_69A

Что такое “Кейсы КС” и “Кейсы КС ГО”?

“Кейсы КС” (или “Кейсы CS”) и “Кейсы КС ГО” (CS:GO) — это виртуальные контейнеры, которые используются в играх Counter-Strike (КС), включая Counter-Strike: Global Offensive (CS:GO) и его обновленную версию Counter-Strike 2 (CS2). Внутри этих кейсов находятся различные игровые предметы — скины для оружия, ножи, перчатки и другие косметические элементы, которые игроки могут получить и использовать в игре для украшения своего инвентаря.

Как это работает?

1. **Регистрация**: Вы заходите на сайт и регистрируетесь, обычно через Steam, чтобы связать свой игровой аккаунт.

2. **Пополнение баланса**: Нужно внести деньги на сайт (например, через карту, криптовалюту или электронные кошельки), чтобы купить кейсы или внутриигровую валюту.

3. **Выбор кейса**: На сайте представлены разные кейсы с указанием возможных наград (от дешевых скинов до редких ножей) и их стоимости.

4. **Открытие кейса**: Вы выбираете кейс, оплачиваете его и открываете. Система случайным образом определяет, какой предмет вы получите.

5. **Вывод выигрыша**: Если вам повезло, вы можете вывести скин в Steam и использовать его в игре.

Чем отличается “Кейсы КС” от “Кейсы КС ГО”?

– **Кейсы КС**: Общий термин, который может относиться к кейсам в любой версии Counter-Strike, включая CS2.

– **Кейсы КС ГО**: Конкретно кейсы из CS:GO, которые были популярны до выхода CS2. Теперь многие платформы, адаптируют их под CS2, но скины из CS:GO все еще совместимы с новой игрой.

Если ты хочешь попробовать, начни с малого — внеси небольшую сумму и протестируй, как все работает. Например, выбери дешевый кейс и посмотри, что выпадет. Это поможет понять механику без больших рисков.

https://yrr.ens.mybluehost.me/index.php/Cs2case_87T

Что такое “Кейсы КС” и “Кейсы КС ГО”?

“Кейсы КС” (или “Кейсы CS”) и “Кейсы КС ГО” (CS:GO) — это виртуальные контейнеры, которые используются в играх Counter-Strike (КС), включая Counter-Strike: Global Offensive (CS:GO) и его обновленную версию Counter-Strike 2 (CS2). Внутри этих кейсов находятся различные игровые предметы — скины для оружия, ножи, перчатки и другие косметические элементы, которые игроки могут получить и использовать в игре для украшения своего инвентаря.

Как это работает?

1. **Регистрация**: Вы заходите на сайт и регистрируетесь, обычно через Steam, чтобы связать свой игровой аккаунт.

2. **Пополнение баланса**: Нужно внести деньги на сайт (например, через карту, криптовалюту или электронные кошельки), чтобы купить кейсы или внутриигровую валюту.

3. **Выбор кейса**: На сайте представлены разные кейсы с указанием возможных наград (от дешевых скинов до редких ножей) и их стоимости.

4. **Открытие кейса**: Вы выбираете кейс, оплачиваете его и открываете. Система случайным образом определяет, какой предмет вы получите.

5. **Вывод выигрыша**: Если вам повезло, вы можете вывести скин в Steam и использовать его в игре.

Чем отличается “Кейсы КС” от “Кейсы КС ГО”?

– **Кейсы КС**: Общий термин, который может относиться к кейсам в любой версии Counter-Strike, включая CS2.

– **Кейсы КС ГО**: Конкретно кейсы из CS:GO, которые были популярны до выхода CS2. Теперь многие платформы, адаптируют их под CS2, но скины из CS:GO все еще совместимы с новой игрой.

Если ты хочешь попробовать, начни с малого — внеси небольшую сумму и протестируй, как все работает. Например, выбери дешевый кейс и посмотри, что выпадет. Это поможет понять механику без больших рисков.

https://www.honkaistarrail.wiki/index.php?title=User:JannieLabarre

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Your site is very nice, the articles are great, I wish you continued success, I love your site very much, I will visit it constantly

Что такое “Кейсы КС” и “Кейсы КС ГО”?

“Кейсы КС” (или “Кейсы CS”) и “Кейсы КС ГО” (CS:GO) — это виртуальные контейнеры, которые используются в играх Counter-Strike (КС), включая Counter-Strike: Global Offensive (CS:GO) и его обновленную версию Counter-Strike 2 (CS2). Внутри этих кейсов находятся различные игровые предметы — скины для оружия, ножи, перчатки и другие косметические элементы, которые игроки могут получить и использовать в игре для украшения своего инвентаря.

Как это работает?

1. **Регистрация**: Вы заходите на сайт и регистрируетесь, обычно через Steam, чтобы связать свой игровой аккаунт.

2. **Пополнение баланса**: Нужно внести деньги на сайт (например, через карту, криптовалюту или электронные кошельки), чтобы купить кейсы или внутриигровую валюту.

3. **Выбор кейса**: На сайте представлены разные кейсы с указанием возможных наград (от дешевых скинов до редких ножей) и их стоимости.

4. **Открытие кейса**: Вы выбираете кейс, оплачиваете его и открываете. Система случайным образом определяет, какой предмет вы получите.

5. **Вывод выигрыша**: Если вам повезло, вы можете вывести скин в Steam и использовать его в игре.

Чем отличается “Кейсы КС” от “Кейсы КС ГО”?

– **Кейсы КС**: Общий термин, который может относиться к кейсам в любой версии Counter-Strike, включая CS2.

– **Кейсы КС ГО**: Конкретно кейсы из CS:GO, которые были популярны до выхода CS2. Теперь многие платформы, адаптируют их под CS2, но скины из CS:GO все еще совместимы с новой игрой.

Если ты хочешь попробовать, начни с малого — внеси небольшую сумму и протестируй, как все работает. Например, выбери дешевый кейс и посмотри, что выпадет. Это поможет понять механику без больших рисков.

http://wiki.algabre.ch/index.php?title=Benutzer:ElmaFelan967242

Что такое “Кейсы КС” и “Кейсы КС ГО”?

“Кейсы КС” (или “Кейсы CS”) и “Кейсы КС ГО” (CS:GO) — это виртуальные контейнеры, которые используются в играх Counter-Strike (КС), включая Counter-Strike: Global Offensive (CS:GO) и его обновленную версию Counter-Strike 2 (CS2). Внутри этих кейсов находятся различные игровые предметы — скины для оружия, ножи, перчатки и другие косметические элементы, которые игроки могут получить и использовать в игре для украшения своего инвентаря.

Как это работает?

1. **Регистрация**: Вы заходите на сайт и регистрируетесь, обычно через Steam, чтобы связать свой игровой аккаунт.

2. **Пополнение баланса**: Нужно внести деньги на сайт (например, через карту, криптовалюту или электронные кошельки), чтобы купить кейсы или внутриигровую валюту.

3. **Выбор кейса**: На сайте представлены разные кейсы с указанием возможных наград (от дешевых скинов до редких ножей) и их стоимости.

4. **Открытие кейса**: Вы выбираете кейс, оплачиваете его и открываете. Система случайным образом определяет, какой предмет вы получите.

5. **Вывод выигрыша**: Если вам повезло, вы можете вывести скин в Steam и использовать его в игре.

Чем отличается “Кейсы КС” от “Кейсы КС ГО”?

– **Кейсы КС**: Общий термин, который может относиться к кейсам в любой версии Counter-Strike, включая CS2.

– **Кейсы КС ГО**: Конкретно кейсы из CS:GO, которые были популярны до выхода CS2. Теперь многие платформы, адаптируют их под CS2, но скины из CS:GO все еще совместимы с новой игрой.

Если ты хочешь попробовать, начни с малого — внеси небольшую сумму и протестируй, как все работает. Например, выбери дешевый кейс и посмотри, что выпадет. Это поможет понять механику без больших рисков.

https://www.pilotoschile.cl/forums/users/nydiabrose33/edit/?updated=true/users/nydiabrose33/

Мы осуществляет сопровождением иностранных граждан в северной столице.

Оказываем содействие в подготовке документов, временной регистрации, и вопросах, связанных с трудоустройством.

Наши эксперты помогают по миграционным нормам и дают советы оптимальные варианты.

Помогаем в оформлении ВНЖ, так и с гражданством.

Благодаря нам, процесс адаптации станет проще, решить все юридические формальности и уверенно чувствовать себя в Санкт-Петербурге.

Пишите нам, для консультации и помощи!

https://spb-migrant.ru/

Buying medicine from e-pharmacies is much easier than going to a physical pharmacy.

You don’t have to deal with crowds or think about closing times.

E-pharmacies allow you to order your medications from home.

Many websites have special deals compared to physical stores.

http://atscaf.plongee.free.fr/phpBB3/viewtopic.php?f=25&t=9938

Plus, it’s possible to browse alternative medications easily.

Quick delivery makes it even more convenient.

What do you think about ordering from e-pharmacies?

Online blackjack flows—good mix!

my blog … http://www.uabb.net/33136/plinko.org.ua/

Online casinos can pull—set edge!

my website – https://www.synfig.org/issues/thebuggenie/synfig/issues/10126

Фанаты слотов всегда могут найти актуальное обходную ссылку онлайн-казино Champion и наслаждаться любимыми слотами.

На сайте доступны разнообразные слоты, от олдскульных до новых, и последние автоматы от мировых брендов.

Если главный ресурс временно заблокирован, рабочее зеркало Champion даст возможность обойти ограничения и продолжить игру.

чемпион казино

Все возможности сохраняются, включая регистрацию, пополнение счета и кэш-ауты, и, конечно, бонусную систему.

Пользуйтесь проверенную альтернативный адрес, и не терять доступ к казино Чемпион!

I won spins online and got $500—sweet score!

Also visit my site … https://plexuss.com/p/pRK4mVoBDbDkNOVnal2EONvnG

The slot themes online glow—play on!

Have a look at my web blog – https://www.lacarpa.com.mx/post/llama-sheinbaum-a-estados-unidos-a-combatir-el-narcotr%C3%A1fico-dentro-de-sus-fronteras?commentId=78fb9e0e-60e8-4878-97af-8af04d774fbe

Online casinos need grip—too loose!

Feel free to visit my blog … https://www.dmxzone.com/support/13984/topic/154554/

Online casinos need tighter rules—too many fakes!

Here is my web-site – https://www.fimfiction.net/blog/1065678/plinko

Vigor Prime packs a punch in a tiny package—love it.

https://seowiki.io/index.php/Benutzer:NanceeJephcott

The live games online rock—fan love!

my blog post :: https://www.thesims3.com/myBlog.html?persona=sasafarasasa&showBlogMasterPopup=false

The mobile casino apps crash too much—ugh!

Here is my page https://www.myvipon.com/post/1561374/vipzino-promo-code-amazon-coupons

I wish online casinos had better mobile apps; some are so glitchy!

Feel free to surf to my web blog :: https://robotech.com/forums/viewthread/2233694

Online gambling is too easy to access—needs more barriers!

My site: https://b.cari.com.my/home.php?mod=space&uid=2604902&do=blog&quickforward=1&id=522698

Что такое BlackSprut?

Платформа BlackSprut удостаивается интерес разных сообществ. В чем его особенности?

Эта площадка обеспечивает широкие функции для тех, кто им интересуется. Интерфейс системы отличается функциональностью, что делает платформу интуитивно удобной даже для новичков.

Необходимо помнить, что данная система имеет свои особенности, которые делают его особенным в определенной среде.

Говоря о BlackSprut, стоит отметить, что многие пользователи выражают неоднозначные взгляды. Некоторые отмечают его удобство, а кто-то оценивают его неоднозначно.

Таким образом, данный сервис остается объектом интереса и привлекает внимание широкой аудитории.

Рабочее зеркало к BlackSprut – узнайте у нас

Хотите узнать свежее зеркало на BlackSprut? Мы поможем.

bs2best at

Периодически ресурс перемещается, поэтому нужно знать актуальное ссылку.

Мы мониторим за актуальными доменами и готовы поделиться актуальным линком.

Посмотрите актуальную ссылку прямо сейчас!

Душевые кабины: комфорт и практичность в ванной комнате

Душевые кабины давно стали неотъемлемой частью современных ванных комнат. Они сочетают в себе удобство, стиль и функциональность, что делает их популярным выбором для домов и квартир. В отличие от традиционных ванн, душевые кабины занимают меньше места, экономят воду и предлагают множество дополнительных опций, которые делают принятие душа более комфортным. В этой статье мы рассмотрим, почему душевые кабины так востребованы, какие виды существуют и на что обратить внимание при выборе.

Преимущества душевых кабин

Одно из главных достоинств душевых кабин — это их компактность. В небольших ванных комнатах, где каждый сантиметр на счету, душевая кабина позволяет рационально использовать пространство. Она идеально подходит для тех, кто ценит минимализм и практичность. Кроме того, душевые кабины помогают экономить воду, так как принятие душа обычно требует меньше ресурсов, чем наполнение ванны.

Еще одно преимущество — разнообразие функций. Современные модели оснащаются гидромассажем, подсветкой, встроенным радио и даже парогенераторами, превращающими кабину в мини-сауну. Это делает их не только средством гигиены, но и способом расслабления после долгого дня. Также душевые кабины легко чистить, а их закрытая конструкция предотвращает разбрызгивание воды по всей комнате.

Виды душевых кабин

Душевые кабины бывают разных типов, и выбор зависит от ваших потребностей и особенностей помещения. Самый простой вариант — это открытые кабины. Они состоят из поддона и стенок, которые примыкают к стенам ванной комнаты. Такие модели недорогие и подходят для маленьких пространств, но они не обеспечивают полной герметичности.

Закрытые душевые кабины — более популярный выбор. Они имеют крышу и полностью изолированы, что позволяет сохранять тепло и использовать дополнительные функции, такие как пар или ароматерапия. Эти модели дороже, но предлагают больше комфорта и возможностей.

Также существуют комбинированные варианты — душевые кабины с ванной. Они подойдут тем, кто не хочет отказываться от возможности полежать в горячей воде, но при этом ценит удобство душа. Такие модели обычно больше по размеру и требуют просторной ванной комнаты.

Материалы и дизайн

При выборе душевой кабины важно обратить внимание на материалы. Поддоны чаще всего изготавливают из акрила, стали или керамики. Акриловые поддоны легкие, теплые на ощупь и доступны по цене, но могут царапаться. Стальные поддоны прочнее, но холоднее и шумят под струей воды. Керамика долговечна и выглядит эстетично, но она тяжелая и хрупкая.

Стенки и двери обычно делают из закаленного стекла или пластика. Стекло прочнее, выглядит дороже и легче моется, тогда как пластик дешевле, но со временем может помутнеть. Дизайн тоже играет роль: прозрачные, матовые или тонированные стенки позволяют подобрать кабину под стиль интерьера.

Как выбрать душевую кабину

Перед покупкой стоит учесть несколько моментов. Во-первых, размеры. Измерьте пространство в ванной комнате, чтобы кабина не загромождала помещение. Во-вторых, определитесь с функциями: нужны ли вам гидромассаж или парогенератор, или достаточно базовой модели. В-третьих, проверьте качество сборки и репутацию производителя. Надежные бренды обычно предлагают гарантию и запасные части.

Также важно подумать о монтаже. Установка душевой кабины требует правильного подключения к водопроводу и канализации, поэтому лучше доверить это профессионалам. Если ванная комната нестандартной формы, можно заказать кабину по индивидуальным размерам.

Уход за душевой кабиной

Чтобы душевая кабина служила долго, за ней нужно правильно ухаживать. После каждого использования рекомендуется протирать стенки и поддон мягкой тряпкой, чтобы избежать налета от воды. Для чистки лучше использовать специальные средства для стекла и акрила, избегая агрессивных химикатов. Регулярно проверяйте уплотнители и фурнитуру, чтобы предотвратить протечки.

https://championsleage.review/wiki/Cabin_87L

Душевые кабины: комфорт и практичность в ванной комнате

Душевые кабины давно стали неотъемлемой частью современных ванных комнат. Они сочетают в себе удобство, стиль и функциональность, что делает их популярным выбором для домов и квартир. В отличие от традиционных ванн, душевые кабины занимают меньше места, экономят воду и предлагают множество дополнительных опций, которые делают принятие душа более комфортным. В этой статье мы рассмотрим, почему душевые кабины так востребованы, какие виды существуют и на что обратить внимание при выборе.

Преимущества душевых кабин

Одно из главных достоинств душевых кабин — это их компактность. В небольших ванных комнатах, где каждый сантиметр на счету, душевая кабина позволяет рационально использовать пространство. Она идеально подходит для тех, кто ценит минимализм и практичность. Кроме того, душевые кабины помогают экономить воду, так как принятие душа обычно требует меньше ресурсов, чем наполнение ванны.